molds

MOULDS

Our Perforating Machines are capable of making many types of designs by simply substituting a particular one called a PRINT. Depending on the type of processing that is done we can have different types of designs. In addition to this, the final design is composed of a series of synchronized avenzaments.

Processing

Thanks to our modular and flexible molds we can make completely different types of processing on many different materials ; These are the possible processing ;

PERFORMING

Leather perforation is a mechanical process that involves the total removal of chips from the material, using shaped dies of various shapes and sizes, including complex ones. The repetition of these perforations composes the final design.

ENGRAVING

Leather engraving is a process of etching the material, using cutting dies of various shapes and sizes, including complex ones. The repetition of these processes composes the final design.

CUT

Leather cutting is a process of physically cutting the material from side to side. Die-cuts of various shapes and sizes are used for this operation. The placement and orientation of these elements is critically important to the final design.

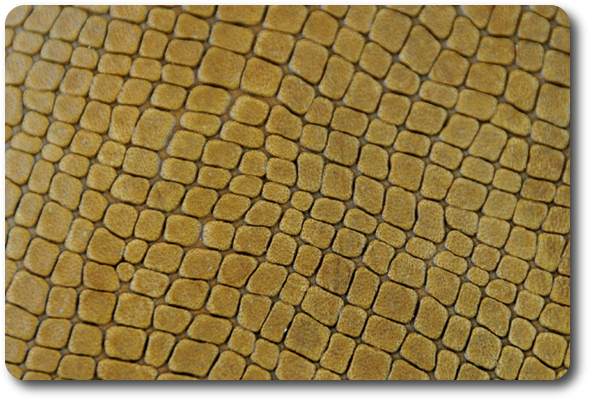

By printing we mean processing normally done with a hot mold. Processing involves impressing a more or less geometric shape on the material. Repetition of this shape enables the final design.

PLACING

Plating is a special process, performed by heat, whereby a printed and/or colored adhesive sheet is glued onto the material. The action of heat allows the melting of the glue present on the adhesive and subsequent bonding to the material.

COMBINED

By combined processing we mean double processing done simultaneously. The attached example shows drilling with material removal and hot plating. The final effect is striking.